Softmounts in Commercial Laundry – The Science of Spring Suspension

Softmounts in Commercial Laundry – The Science of Spring Suspension

Over the years, there has been quite a bit of confusion regarding the choice of machine type for a commercial laundry. Unless the laundry was on an upper floor, conventional wisdom said choose a hardmount commercial washer due to the lower perceived pricing of a hardmount.

Today, with concrete pricing around $150 per cubic yard, that small amount of floor improvement required for yesterday’s machine is suddenly a very expensive proposition. Add in construction labor, permitting, plus curing time and you are looking at a seriously costly venture. A softmount needs none of the high dollar reinforced concrete that an old-fashioned hardmount.

How does a softmount washing machine solve these problems?

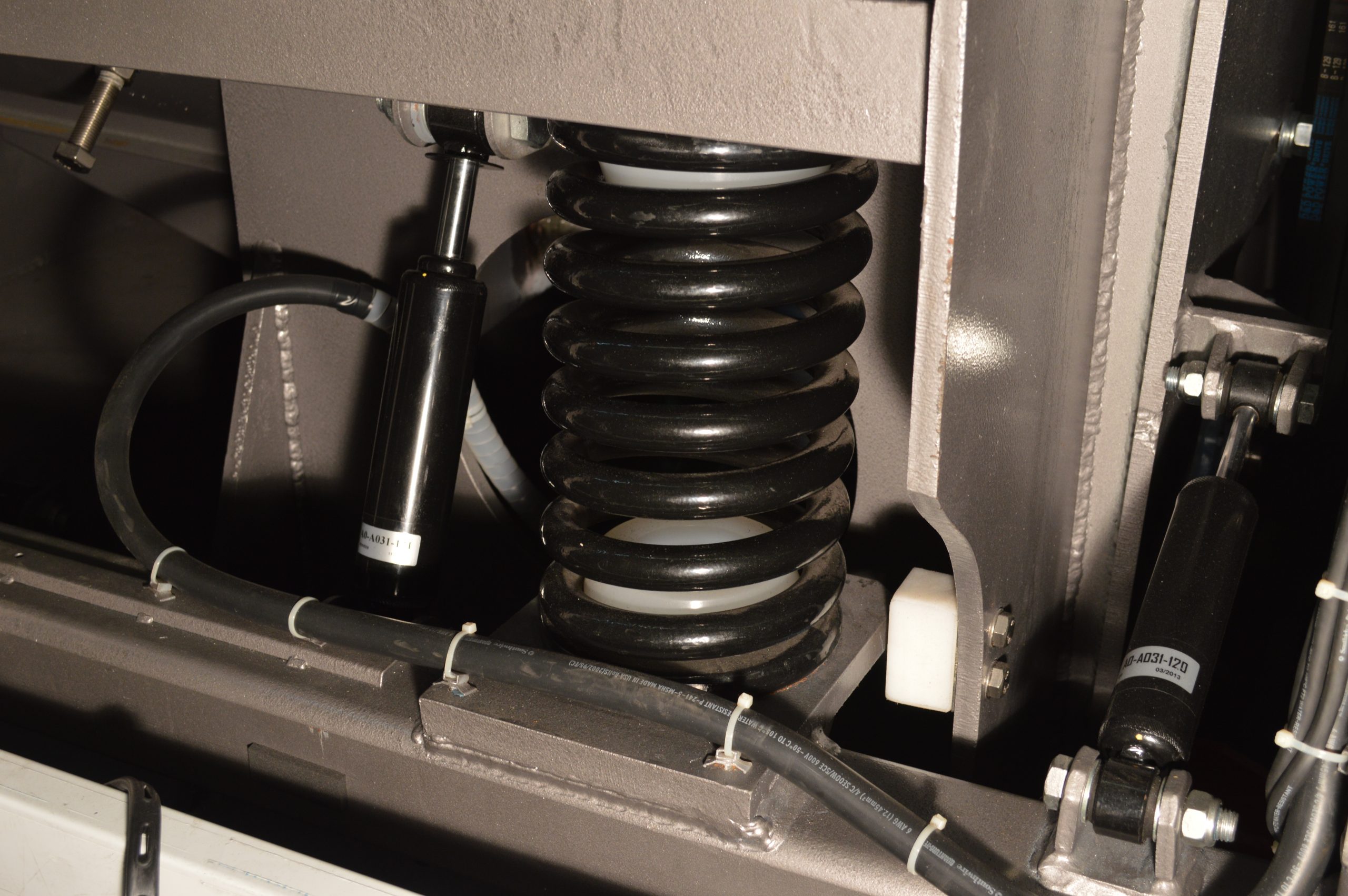

- Spring suspension: Instead of transferring all of the forces generated during each spin through the frame of the machine and into the floor, a softmount machine uses springs and shock absorbers to absorb these forces. Instead of many thousands of pounds of force to the floor, the softmount only sends a small percentage. This translates directly into a less expensive foundation for the machine.

- Inverter drive: Most modern machines use an inverter drive to control the speed of the commercial laundry washer’s cylinder – even old-fashioned hardmounts are now using this technology. Many manufacturers also use inverter technology to determine how badly out of balance the machine is prior to performing a spin. This is a much safer alternative to limit switches and other compromises and makes sure that an unsafe load can’t spin and cause damage or injury.

- Modern computer control: A mechanical timer system could never hope to control all of the variables of a modern softmount washer. Redistribution routines, allowing the machine to fix an out of balance problem, are not possible with a mechanical timer. Plus, modern computer controls allow for a tremendous variety in programming enabling special wash processes like ozone and wetcleaning. These technologies would not be possible without a modern control.

- Computer design software: Modern computers are amazing tools for engineers to apply. Computers allow the engineer to ensure that the design of the machine will withstand the forces generated over the life of the machine. Breaking frames in a washer was a real concern just 20 years ago. This is no longer a worry for a modern washer due to the technological advances in computers.

A softmount also provides other benefits to the wise laundry owner:

- Time is saved during installation, as no cutting of the floor is required, nor any of the other things that must be done to prepare the floor for a hardmount. There also is no wait for the concrete to cure, no waiting for the construction crew to show up, and no wait for a construction permit.

- Softmounts typically spin at much higher speeds that hardmounts, removing quite a bit more water from the goods. This means that the dryer has less work to do, saving time and energy, plus the dryer will get the job done more quickly, further increasing the amount of work the laundry can do in one day. All of this magic can happen within the same amount of laundry square feet, increasing the overall efficiency of the laundry.

- Softmounts do not reduce the extract force if the load is slightly out of balance. You may have seen hardmount machines advertised which claim to extract at very high speeds, comparable to a softmount. These types of hardmount machines only extract at these very high speeds under perfect conditions. If the load is not almost perfectly balanced when it is time to spin, the hardmount machine will automatically slow down so that it does not pull away from the floor and chase someone around the room. A high speed hardmount of this type will average a much lower extract force than the comparable softmount, and require more energy and time from the dryer.

Softmounts are an excellent choice for any commercial laundry for both new construction and replacement. Quicker installation time and a lower installation cost plus increased efficiency of the washer and dryer team due to the higher spin speeds will save money and time over the life of the machines in your commercial laundry. Softmounts truly are the wave of the future!

Comments