Humidity Sensing Saves Time, Energy, and Money in Your Commercial Laundry

Humidity Sensing Saves Time, Energy, and Money

We all know that tumble dryers aren’t particularly gentle, but along with the tumbling action, there are other dangers lurking in the dryer. Over drying can damage or shrink fabrics, and a moisture sensor minimizes that possibility. Commercial Laundry dryers equipped with a moisture sensor can save up to 15% on energy costs over standard timed drying by measuring the remaining water left in the goods, and stopping the drying process when they are dry.

There are quite a few worthwhile benefits of moisture sensing:

- Less wear and tear on goods

- Lower energy costs

- More loads per week

- Saves wear and tear on the dryer

- Automatically adjusts to different sized loads

- Automatically adjusts for different fabric types

- Excellent for special processes like wet cleaning

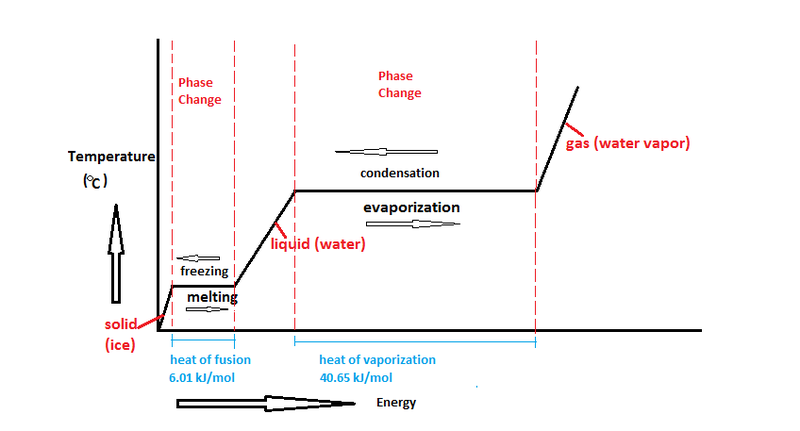

Humidity sensing allows for a gentler drying process, as heat damage to the goods mainly occurs after the water has been removed from the goods via evaporation. As the dryer adds heat, the energy is used to heat the goods and the water in the goods to the point where the water vaporizes. Water has a very high latent heat, meaning it takes quite a bit of energy to change it from a liquid to a gas. In a dryer, this energy is supplied by the fuel type (gas, steam, or electric heating) and typically heats the airstream much higher than the boiling point of water (212F or 100C). However, the water contained by the goods can only be heated to its boiling point so the maximum temperature the goods see is 212F or 100C. After the water is removed, the goods will be able to absorb the full amount of heat from the air stream and this is what causes fabric damage, wastes energy, and wastes time, leading to lost profits.

Humidity sensing also saves wear and tear on your dryer. Let’s do the math (I love to do the math!): Assume we save 5 minutes per cycle, we run the dryer 8 cycles per day, that’s 40 minutes per shift x 250 working days per year equals 167 less hours the dryer runs per year or an additional 21 days saved per year. If the average dryer life is 10 years, that’s almost an extra year of service you’d get out of an average machine running one shift per day. Not too shabby at all.

Humidity sensing is another fantastic tool in an efficient commercial or industrial laundry that is critical for utility savings as well as adding life expectancy to the laundered items and should be insisted upon for any dryer purchase.

Jamds

October 17, 2022 - 9:28 pm

Yes how hot should the water be when set on hot an if so we ould it Trans Fer some heat in the glass what the correct way to see if it’s running at the tight temp mode su64cc

Al Adcock

October 18, 2022 - 11:43 am

Hi Jamds,

I would suggest referring to the Installation and Operation Manual for your Wascomat machine. Generally speaking, when you select a hot cycle, you should get the water temperature into the machine that your water heater provides. This is usually around 140F for best results. Definitely check to make sure that the hot water and cold water hoses are connected to the correct inlets on the back of the machine.

Good Luck!

Jamds

October 17, 2022 - 9:32 pm

Hello I’m trying to find out if my su640cc washer is working correctly when the water fills its cold when it’s running its cold how can I check my temperature when on the hot modle

John Hays

January 21, 2024 - 2:37 am

I am wanting to fit humidity controls to large commercial laundry dryers.

What do you recommend?

Al Adcock

January 22, 2024 - 10:03 am

Hi John,

Thanks for your question. Firstly, I’d contact the manufacturer of your dryers and inquire about an upgrade path for you current controls. Given that the dryers are the least expensive machines in the laundry, it may be worth doing an analysis on replacement based on fuel savings, as the payback may be quicker than expected. Of course, this will depend on the age and condition of you current machines. How much are you spending on maintenance for these machines currently? Don’t forget to factor in maintenance costs into your calculations. Good luck!

Al