Safety in your Commercial Laundry

Safety is of primary importance when operating your commercial laundry. Injuries lead to lost time and productivity in the best case, while leaving the business open to lawsuits in the worst case. While all manufacturers do what they can to make the machines as safe as possible, poor maintenance and usage can undo all of this good work and lead to injury if best practices are not followed.

Safety is of primary importance when operating your commercial laundry. Injuries lead to lost time and productivity in the best case, while leaving the business open to lawsuits in the worst case. While all manufacturers do what they can to make the machines as safe as possible, poor maintenance and usage can undo all of this good work and lead to injury if best practices are not followed.

General safety must be observed in a laundry just as in any other business. Common issues in a laundry include water on the floor (a slipping hazard), excess lint accumulation (a fire hazard), and high temperatures (heat related injury risk). Any spills should be taken care of immediately, while leaks or other sources of water should be dealt with during routine maintenance. Lint and dirt or dust accumulation is dangerous due to the fire hazard it causes. Lint is extremely flammable and should be removed frequently. Dangerous areas include burner areas of dryers, electrical panels, electrical disconnects, and other areas where high heat or high voltage is near. A lint mitigation program should be implemented in every commercial laundry to prevent damage from flash fires. During hot times of the year, hydration and breaks are important to avoid heat related injury.

General safety must be observed in a laundry just as in any other business. Common issues in a laundry include water on the floor (a slipping hazard), excess lint accumulation (a fire hazard), and high temperatures (heat related injury risk). Any spills should be taken care of immediately, while leaks or other sources of water should be dealt with during routine maintenance. Lint and dirt or dust accumulation is dangerous due to the fire hazard it causes. Lint is extremely flammable and should be removed frequently. Dangerous areas include burner areas of dryers, electrical panels, electrical disconnects, and other areas where high heat or high voltage is near. A lint mitigation program should be implemented in every commercial laundry to prevent damage from flash fires. During hot times of the year, hydration and breaks are important to avoid heat related injury.

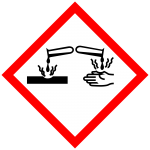

Chemical safety is likely the most common area of concern in a laundry, since a typical laundry will have highly concentrated bleach as well as concentrated detergent and softener. Eye damage from any of the chemicals can happen very quickly, so eye protection is imperative when handling any laundry chemicals. It may seem silly to put on safety glasses when changing the chemical containers, but your eyesight is definitely worth the small amount of effort required to don safety glasses. Always wash your hands immediately after contact with the chemical containers in case of accidental contact – you do not want to touch any part of yourself with concentrated detergents or other commercial laundry chemicals (eyes, mouth, etc.)! If any chemicals get on your clothing, a change of garments will become necessary.

Chemical safety is likely the most common area of concern in a laundry, since a typical laundry will have highly concentrated bleach as well as concentrated detergent and softener. Eye damage from any of the chemicals can happen very quickly, so eye protection is imperative when handling any laundry chemicals. It may seem silly to put on safety glasses when changing the chemical containers, but your eyesight is definitely worth the small amount of effort required to don safety glasses. Always wash your hands immediately after contact with the chemical containers in case of accidental contact – you do not want to touch any part of yourself with concentrated detergents or other commercial laundry chemicals (eyes, mouth, etc.)! If any chemicals get on your clothing, a change of garments will become necessary.

Mechanical safety is also of critical importance. While all of the laundry equipment was designed with safety in mind, these safety measures go out of the window if the machine is not operated as the manufacturer intended. Missing panels, covers, or guards make it much easier for an injury to occur. Anytime maintenance is performed, all panels must be reinstalled to ensure no one can accidentally come into contact with moving parts. Bypassing any safety device is also an extremely bad idea that can land a small business in trouble. These devices are in place to prevent injuries to laundry personnel, and must be operating properly. If there are any malfunctions to these important devices, the equipment must be properly locked out and tagged out while awaiting service.

Mechanical safety is also of critical importance. While all of the laundry equipment was designed with safety in mind, these safety measures go out of the window if the machine is not operated as the manufacturer intended. Missing panels, covers, or guards make it much easier for an injury to occur. Anytime maintenance is performed, all panels must be reinstalled to ensure no one can accidentally come into contact with moving parts. Bypassing any safety device is also an extremely bad idea that can land a small business in trouble. These devices are in place to prevent injuries to laundry personnel, and must be operating properly. If there are any malfunctions to these important devices, the equipment must be properly locked out and tagged out while awaiting service.

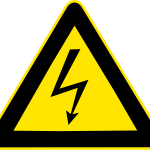

Electrical safety is likely the most important of all. While a mechanical hazard can at least be seen, an electrical hazard typically can not. This is another reason to make sure all electrical enclosure covers are in place during operation. Once servicing of the machines is accomplished, all panels and guards must be reinstalled properly to prevent electrical shock.

Electrical safety is likely the most important of all. While a mechanical hazard can at least be seen, an electrical hazard typically can not. This is another reason to make sure all electrical enclosure covers are in place during operation. Once servicing of the machines is accomplished, all panels and guards must be reinstalled properly to prevent electrical shock.

Lastly, spontaneous combustion is a subject that should not be overlooked in a commercial laundry. Any greasy or oily rags that are laundered have the potential to catch fire in the dryer if the utmost care is not used. Any items left in the dyer overnight must go through the complete drying process without omitting the cool down phase at the end of the drying cycle. If the cool down step is skipped, the high temperatures can cause the goods to catch fire if the goods stop tumbling. While many commercial dryers have some type of fire suppression system today, it is always safest to process the laundry properly so that these devices do not need to come into play. For more information about spontaneous combustion read this information.

Lastly, spontaneous combustion is a subject that should not be overlooked in a commercial laundry. Any greasy or oily rags that are laundered have the potential to catch fire in the dryer if the utmost care is not used. Any items left in the dyer overnight must go through the complete drying process without omitting the cool down phase at the end of the drying cycle. If the cool down step is skipped, the high temperatures can cause the goods to catch fire if the goods stop tumbling. While many commercial dryers have some type of fire suppression system today, it is always safest to process the laundry properly so that these devices do not need to come into play. For more information about spontaneous combustion read this information.

Most of all, a large dose of common sense must be used in the safe operation of a laundry. Vigilance is important, since things that we are commonly exposed to seem to become less dangerous over time. The best course of action is to follow maintenance and safety procedures as outlined in the manuals that come with each piece of commercial laundry equipment. The engineers that have designed the equipment think about safety while creating these wonderful machines that save so much time and labor over doing laundry on a rock by the river. Remember, Safety First!

Most of all, a large dose of common sense must be used in the safe operation of a laundry. Vigilance is important, since things that we are commonly exposed to seem to become less dangerous over time. The best course of action is to follow maintenance and safety procedures as outlined in the manuals that come with each piece of commercial laundry equipment. The engineers that have designed the equipment think about safety while creating these wonderful machines that save so much time and labor over doing laundry on a rock by the river. Remember, Safety First!